Stainless Steel MIM Ball Valve Parts With Drawing

OEM Stainless Steel

Plating:Electroplate,PVD,Sandblasting,Painting,Polishing,Laser Engraving etc.

Certification: All products SGS,CTI and RoHs approved, All material REACH approved.

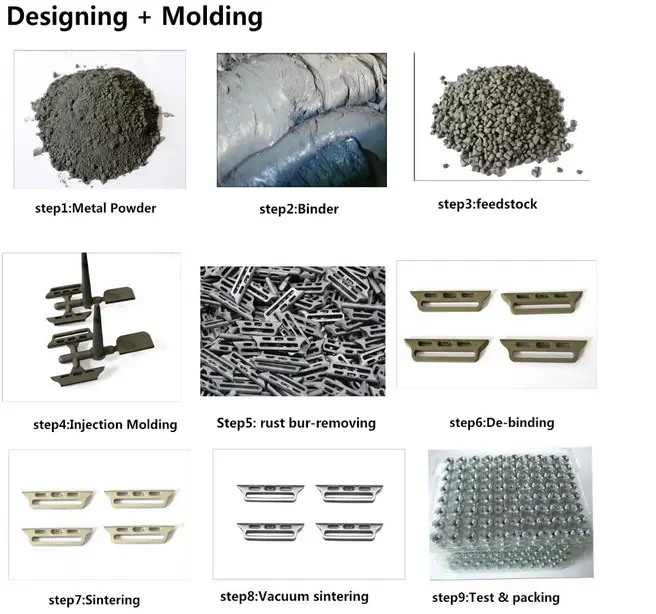

Technology: Powder Injection Molding(PIM)

Material: Stainless steel PIM- 17-4PH

Application: Tap ball valve

Size: 8*8*37 [L * W * H(mm)]

Weight: 18g

Tolerance: ±0.03mm

1) Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio.

2) Suitable for producing products of the same shape and large quantities, low production cost.

3) The production process is not afraid of oxidation, and no material pollution will occur.

4) No subsequent machining processing is required, saving materials and reducing costs.

5) Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy.

1.Technique advantage

Our company has been specialized in MIM and CIM technology for 6 years that possess the mature technology in Metal Injection Molding (MIM) and Ceramic Injection Molding (CIM) . We are a professional company that integrates R&D, production, sale and excellent service in one, which is the

only factory in China currently that specializes in MIM and CIM.

2.Production advantage

Our factor8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world.

4.Brand advantage

Jiehuang MIM company has established brand consciousness, we attached great importance to product quality and company reputation. And we are cooperating with the well-known enterprises and universities at and abroad.

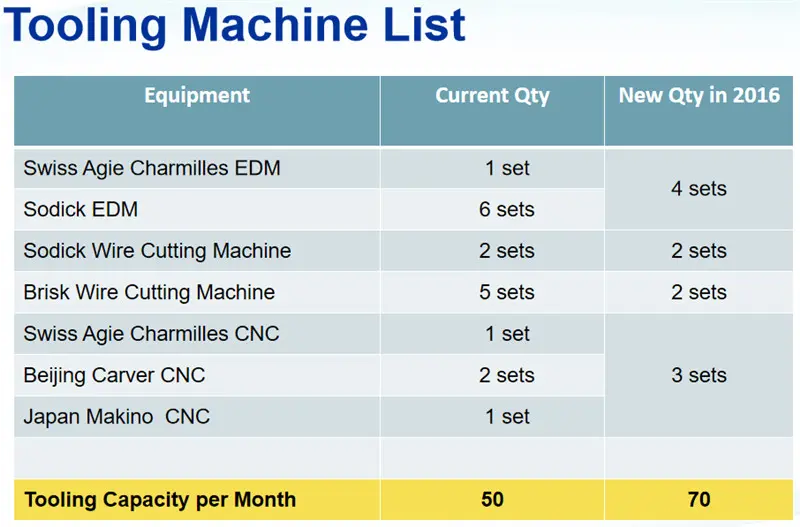

Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace.

8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world.

MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts.

Ningbo Jiehuang Electirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical.

Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City.

Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace.

8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world.

MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts.

Looking forward to growing together with you!

It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company’s proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

Our core manufacturing equipment is imported directly from Germany.

We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.

Strict Quality Control, Rigorous product inspection after mass production

One-stop Metal parts supplier in China