Metal MIM Products For Earphone Parts OEM ODM Metal Injection Molding With Drawing

Technology:Metal Injection Molding .

Weight (KG):0.02 KG

Material:Stainless Steel

Color:silver/gold/black

Tolerance:0.03~0.05 mm

Size:L39.9*3.05mm

| Condition: | New | Type: | Earphone Parts |

| Spare Parts Type: | Earphone Parts | Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided | Marketing Type: | Ordinary Product |

| Material: | Stainless Steel | Plating: | Chrome |

| Warranty: | 1 Year | Key Selling Points: | Long Service Life |

| Weight (KG): | 0.02 KG | Applicable Industries: | Building Material Shops, Manufacturing Plant |

| Weight: | 0.5~200g | Color: | silver/gold/black |

| Shape: | Customized | Tolerance: | 0.03~0.05 mm |

| Technology: | Metal Injection Molding | Size: | L39.9*3.05mm |

| After-sales Service Provided: | Online support | After Warranty Service: | Online support |

MIM is the process that combines powdered metallurgy and plastic injection molding. It offers more design flexibility and the ability to manufacture complex, precise parts in huge quantities.

●10 years metal injection molding manufacturing experience

●TS16949/ISO9001/ISO14001 certificated company

●Breakthrough 0.2mm thickness; develop more than 80 projects annually

●Sintered density can be 7.97g/m3

●Made in house PVD, sand blasting, polish, brush

Stainless Steel(SS3I6L/SS304/SS17-4PH/SS440C)

lron-Based Alloy(Fe2Ni/Fe4Ni/Fe8Ni)

Metal Injection Molding (MIM)

Cost Effective Design Flexibility/ Material Variety and Integrity

Complexity : allows the freedom to manufacture complicated shapes that would be considered cost prohibitive by other methods.

Precision: : +0.3~ +0. 5% tolerance

Weight & Size: 0.1~500g

Section Thickness: 0.2-10MM

Sintered density: 98- 100% dense

Material utilization:>98%

Production Volumes: allow thousands millions of parts, quickly and efficiently

Jiehuang provides a full range of value added service, such as surface finish and assembling.

Majority of them are done in-house, thereby providing al-ound control of quality, delivery and cost

●Heat Treatment

●Magnetic grinding

●Plane grinding

●Passivation

●Electro-polish, hand polish

●PVD

●Sand blasting

●Brush

●Laser engraving

●Silk print

●Paintin

●CNC turning and milling.

●Centerless, ID and OD grinding.

●Fine hole dilling, reaming and burnishing.

●Precision honing.

●Thread rlling and cutting.

●Laser welding, cutting and dilling.

Ningbo Jiehuang Chiyang lectirc Tech Co.,Ltd, We are experts in metal parts such as forging parts, casting parts, metal stamping parts, CNC machining parts, powder metal parts, metal injection molding (MIM) parts, plastic injection parts, sanitary valves, various hardware products and so on. We serve a diverse range of applications in diverse industries – Automotive, Industrial, Electronics and Medical.

Our factory loacted in Cidong Industrial Zone,Cixi, Ningbo City.

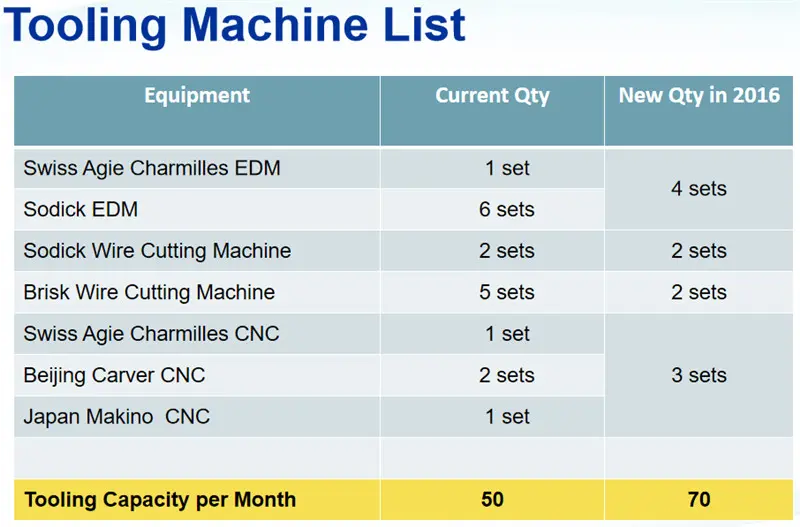

Now we have 16 pieces Injection molding machines, 4 pieces Degreasing furnace and 6 pieces sintering furnace.

8 engineers, 50+ workers, advanced testing equipment, perfect management system and more than 10 years of work experience allow us to serve many top companies around the world.

MIM technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and Other industrial parts.

Looking forward to growing together with you!

It has a registered capital of 33.5 million yuan and is a professional provider of metal injection molding (MIM) technology solutions. Service provider, a high-tech enterprise integrating R&D, production and sales. The company’s proprietary technology belongs to the new materials and high-end equipment fields that the state is currently supporting. The technology can be radiated to many fields such as consumer electronics, medical equipment, auto parts, and iND. Industrial parts.

Through more than 10 years of operation and deep cultivation in the technical field, Company has more than 50+ workers, has 15 production lines with an annual production capacity of over 75 million. The company has passed ISO9001 quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification; The company’s technological innovation has obtained 14 invention patents, 13 utility model patents, 3 scientific and technological achievements, 2 municipal high-tech products, and more than 30 MIM key common technology research results, all of which have achieved industrial application. .

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

Our core manufacturing equipment is imported directly from Germany.

We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.

Strict Quality Control, Rigorous product inspection after mass production

One-stop Metal parts supplier in China