products

- home

- products

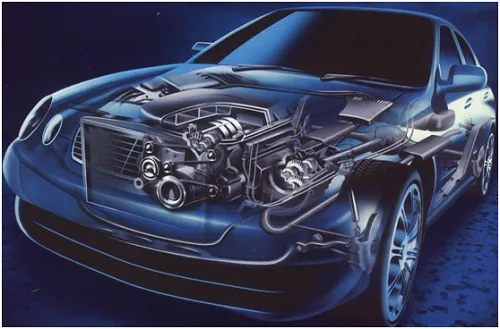

OEM Products

Characteristics of powder metallurgy parts

1. Excellent organizational structure and performance

2. Significant technical and economic benefits;

3. Can produce many materials and products that cannot be produced by other methods (such as: many refractory materials);

4. It is an important and economical forming technology for manufacturing various machine parts; (The ability to obtain parts with the final size and shape, achieving less cutting free machining)

5. The strength of ordinary powder metallurgy products is lower than the corresponding forgings or castings (20~30) %; (There are pores inside the product)

6. The fluidity of the powder in the molding process is not as good as that of liquid metal (there are limitations on the structural shape of the product)

7. Products generally < 10kg

8. High die cost and high powder cost.

9. Suitable for batch or mass production

The structure and processability of powder metallurgy PM parts

Avoid fragile sharp corners in the mold;

Avoid local thin wall of mold and compact;

The cone and inclined plane shall have a small section of straight strip;

Need to have a release cone or rounded corner;

Adapt to the needs of the pressing direction

To make pressing and demoulding easier, powder metallurgy parts’ structures should be as straightforward as possible; It facilitates homogeneous powder filling, compactness, and density; It is advantageous to streamline the die’s construction and lengthen its useful life.

-

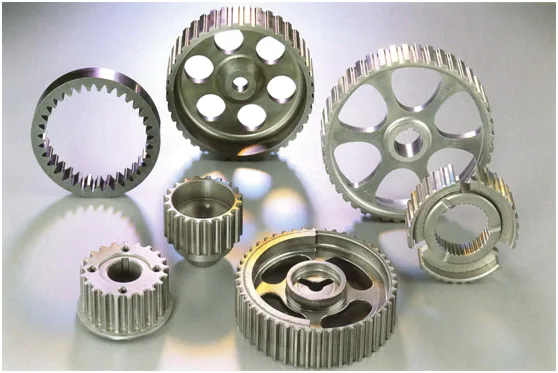

China Precision Casting Starter Aluminum Zinc Die Casting Parts Customized Drawing Design Pulley Flywheel

-

China Factory custom A360 ADC12 die cast aluminum die casting auto spare parts

-

China Factory Customized Die Casting Parts Aluminum Zinc Brass Magnesium Alloy Die Casting Services

-

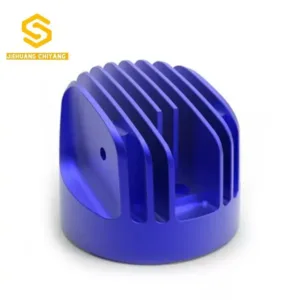

Manufacturer Custom Metal Brass Zinc Die Casting Mould Parts Anodizing Aluminum Die Casting

-

Professional OEM High Precision Custom Die Cast Products Zinc Alloy Aluminum Die Casting

-

OEM China Factory Hardware Mold Injection Metal Aluminum Alloy Zinc Die Casting Parts Manufacturer

-

MIM Metal Injection Molding 316L Stainless Steel textile machinery part mould

-

Custom titanium mim auto parts

-

Micro Gears