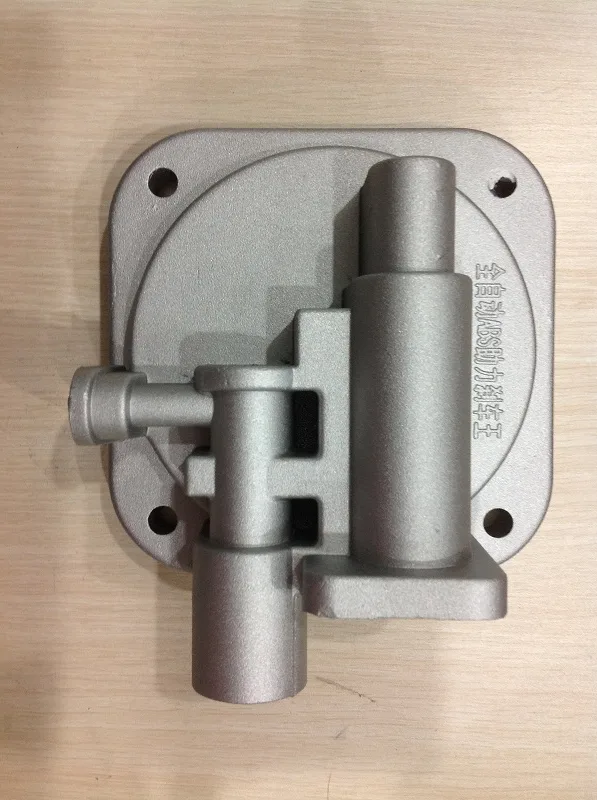

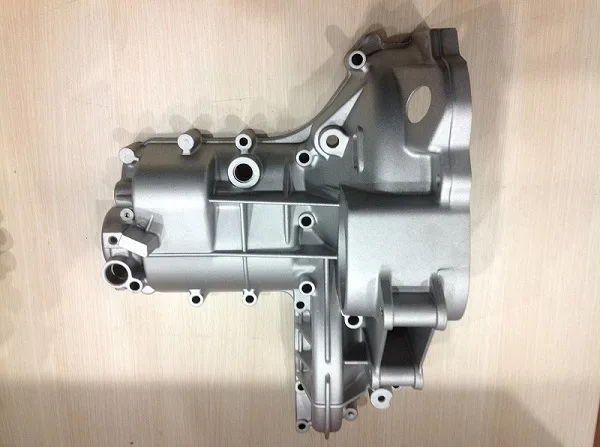

Aluminum die casting

- home

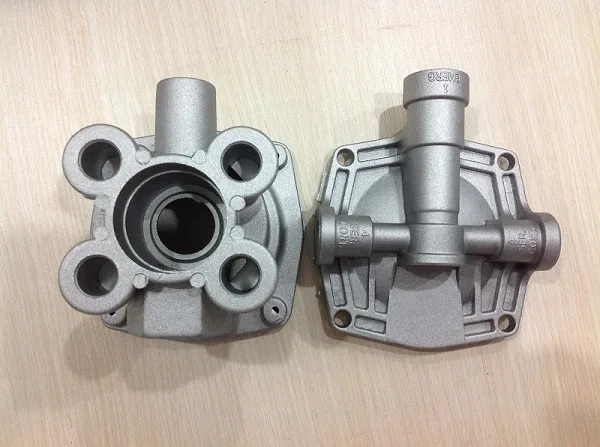

- Aluminum die casting

Describe aluminum Casting in Die meaning

Aluminum's advantages and defects of Die Casting

Aluminum’s advantages and defects of Die Casting

1. High-quality goods

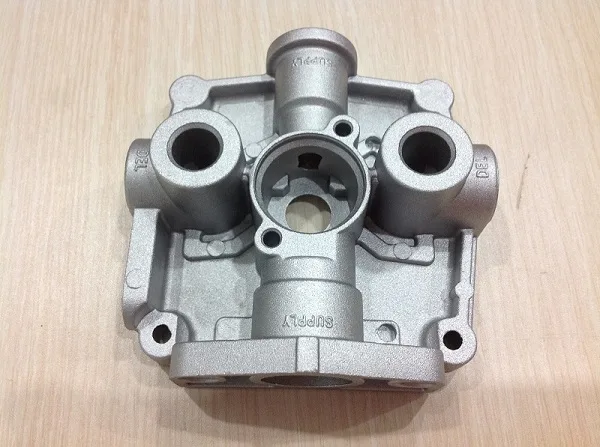

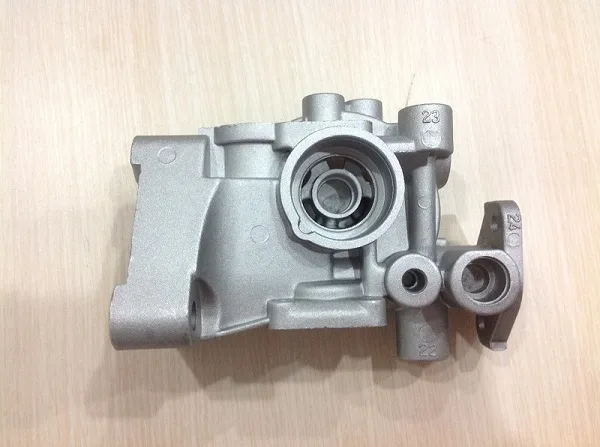

high dimensional precision the same as ISO CT6–CT7. up to CT4, even. improved surface quality. high hardness and strength. The strength surpasses the sand mold’s strength by 30%. But there is a roughly 70% reduction in elongation. stable in all dimensions. Complex castings with thin walls are preferable.

2. High output effectiveness

3000–7000 times of die-casting aluminum components. Days.

3. Affordable mold.

Die-casting molds for aluminum have a long lifespan. up to a million, or even hundreds of thousands of times.

3. Reduction in secondary machining

Aluminum die castings typically don’t need, or almost ever need, machining after casting because of their accurate dimensions and superb surface polish.

It doesn’t just increase the metal’s utilization rate. can significantly cut back on the use of machining tools and labor. For this reason, aluminum die casting is less expensive than aluminum sand casting.

Disadvantages

Small batch production is not a good fit for aluminum die casting.

The primary cause is the high expense of producing die-casting aluminum molds. Production in small batches is not cost-effective.

The gravity casting method for aluminum is a choice for smaller castings.

China aluminium die casting manufacturers

Aluminum die casting auto parts