custom service

- home

- custom service

Choose us ,Choose Simple

Your one-stop metal parts ,Trusted partner of world-renowned companies

DIE CASTING Parts

Die casting process is the use of machine, mold and alloy and other three elements, the pressure, speed and time unified process. Used for metal hot working, the existence of pressure is the main characteristics of die casting process different from other casting methods. Pressure casting is a fast developing special casting method with less cutting in modern metal processing technology

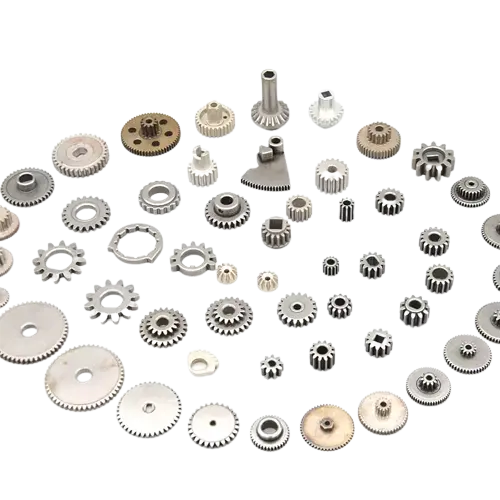

MIM Parts

Metal Injection Molding MIM is a new type of powder metallurgy near net Molding technology developed from the plastic Injection Molding industry.The plastic Injection Molding technology can produce all kinds of complex shape products with low price, but the strength of plastic products is not high. Metal or ceramic powders can be added to plastics to obtain products with high strength and good wear resistance.

PM parts

Powder metallurgy is a process of making metal powder and using metal or alloy (or mixture of metal powder and non-metal powder) powder as raw material, through forming and sintering to obtain metal parts products.

about us

Renting Equipment with Built

Ningbo Jiehuang Chiyang Electronic Tech Co.,Ltd. is a leading one stop metal parts solution provider in China.Our team have many years of experience in developing custom metal parts.we have powder metal manufacturing and metal injection molding parts and Die casting products(Alumimin diecasting and Znic Alloy die casting ) Our products are mainly applied to 3C (Computer, Communication, Consumer Electronics) sectors Auto parts, and industry parts. We will work with you through all phases of project development – from requirement planning, tooling design and build, to FOT and manufacturing, through to the shipping and logistics.Hoping be your First choice!

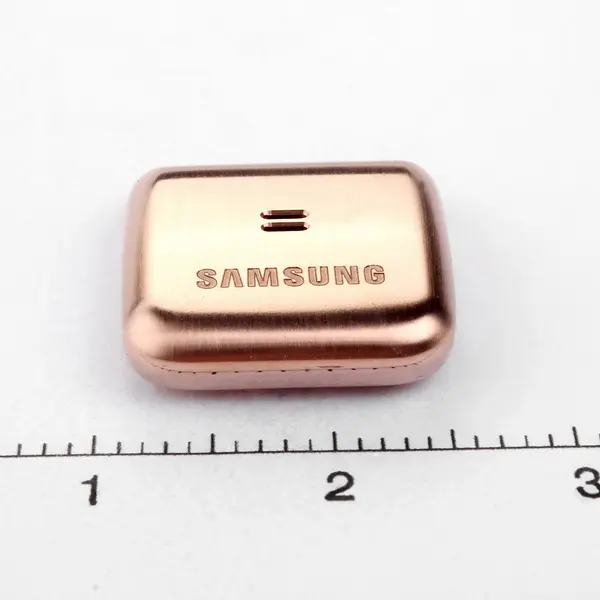

Success Case

Part name:Smart Electronic Door Lock(Painting)

Weight:0.45kg

Material:ADC12

Yearly Volume:800,000sets

DCM: 280T

Part name:Filter Body (Powder painting)

Weight:0.3kg

Material :ADC12

Yearly Volume:80,000pcs

DCM:350T

Why us

Our technical staff has extensive knowledge in creating Metal Parts. We will collaborate with you during every stage of the project’s development, including requirement gathering, tool design and construction, FOT and manufacture, shipping, and logistics.

Engineering Support:

-Support for mechanical engineering includes,

-design and reverse engineering

-manufacturing & process control

-quality improvement

-material selection

-testing

10+ years industry experience

50+ experienced engineers

20,000+ square meters workshop area

ISO 9001/ IATF 16949

Faster quotations and DMF reports

In-depth cooperation of world-renowned companies

+86 13605745108

GET IN TOUCH